Χαρακτηριστικά με μια ματιά

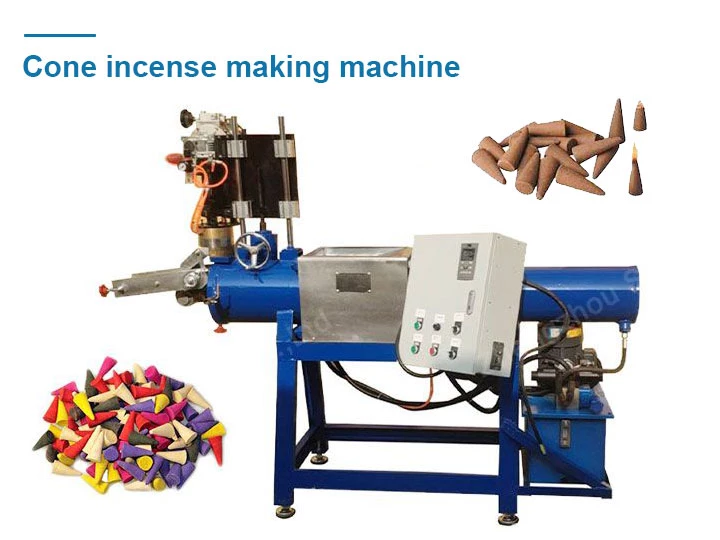

Αυτή η εμπορική μηχανή παρασκευής κώνων θυμιάματος χρησιμοποιείται κυρίως για την επεξεργασία διαφόρων τύπων θυμιάματος σε σχήμα κώνου. Με την αλλαγή των καλουπιών σχηματισμού θυμιάματος κώνου, το μηχάνημα κώνου θυμιάματος μπορεί να επεξεργαστεί κώνους διαφορετικών διαμέτρων και μηκών. Η παραγωγική ικανότητα της μηχανής κώνου κυμαίνεται από 30 έως 240 κώνους ανά λεπτό και η ταχύτητα επεξεργασίας μπορεί να ρυθμιστεί ανάλογα με τις ανάγκες παραγωγής.

Βήματα για να φτιάξετε χωνάκια θυμιάματος

Ανακατεύουμε τη σκόνη θυμιάματος

Το αλεύρι ξύλου, η σκόνη κόλλας και το νερό αναμειγνύονται καλά σε μια συγκεκριμένη αναλογία. Το αλεύρι ξύλου, το νερό και η σκόνη κόλλας είναι οι βασικές πρώτες ύλες για την επεξεργασία του θυμιάματος και ο πελάτης μπορεί να προσθέσει τη σωστή ποσότητα μπαχαρικών σε αυτά ανάλογα με τις συγκεκριμένες ανάγκες επεξεργασίας.

Σχηματισμός κώνου θυμιάματος

Τοποθετήστε τα καλά αναμεμειγμένα υλικά στην είσοδο του μηχανήματος. Το υλικό ωθείται προς τα εμπρός από την υδραυλική μονάδα μέσα στη μηχανή στη μήτρα εξώθησης. Τα καλούπια της μηχανής είναι πάνω και κάτω δίσκοι καλουπιών σε ομάδες. Σε υψηλή ταχύτητα, η αρωματική σκόνη συμπιέζεται γρήγορα σε σχήμα κώνου. Στη συνέχεια, ένας φυσητήρας κοντά στην έξοδο φυσά αυτόματα τους κώνους θυμιάματος που έχουν ήδη σχηματιστεί στο καλούπι προς τα κάτω στον μεταφορικό ιμάντα εξόδου.

Στεγνώστε τα χωνάκια θυμιάματος

Οι φρεσκοεπεξεργασμένοι κώνοι θυμιάματος είναι ακόμα μαλακοί και επιρρεπείς σε σπάσιμο και παραμόρφωση. Πρέπει, λοιπόν, να τα μαζέψουμε και να τα βάλουμε σε διχτυωτό πλαίσιο για να στεγνώσουν.