Features at a Glance

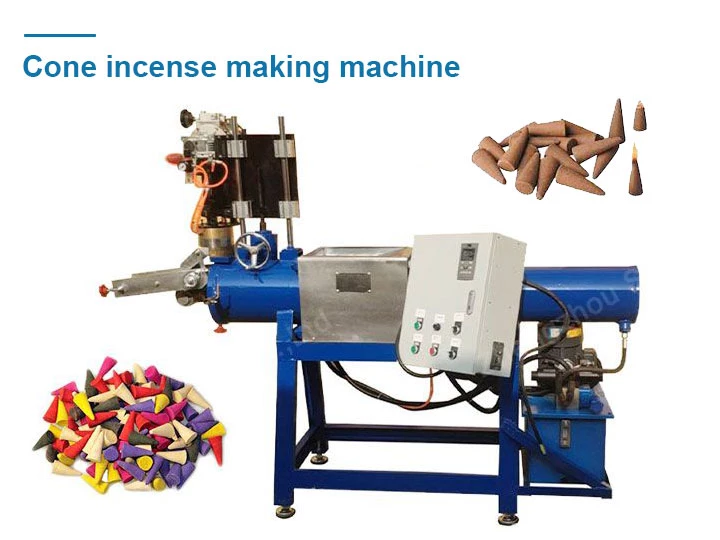

The exceptional continuous backflow incense cone machine specializes in crafting a wide array of incense cones featuring central holes or intricately engraved pagoda shapes. Elevate your production with the automatic waterfall incense cone machine, capable of molding diverse sizes of backflow incense cones through easy mold changeovers.

Notably, this versatile machine also facilitates the creation of vibrant-colored incense cones. Unlock the potential of the reverse flow incense machine and revolutionize your incense cone production.

Features of backflow incense cones

Backflow incense cones, also known as “reverse flow” or “down-flow” incense cones, are a unique type of incense designed to create a mesmerizing visual and aromatic experience. Unlike traditional incense cones that release smoke upwards, backflow cones are crafted in a way that the smoke flows downward, creating a captivating cascading effect.

This captivating phenomenon is made possible by the special hollow interior of the cones, which allows air to be drawn from below, causing the smoke to flow in reverse direction. The result is a stunning visual display where the smoke appears to “flow” like a waterfall or mist, often accompanied by a soothing aroma.

This innovative twist on incense burning has gained popularity for its calming and visually enchanting qualities, making it a favorite choice for relaxation, meditation, and interior décor.

Backflow incense cone machine advantages

- The backflow dhoop cones maker machine is delivered already assembled and ready to use without installation. Furthermore, the machine is very easy to operate, with an operator panel that allows you to set the processing speed. Our factory also sends our customers detailed operating instructions in English and detailed instructional videos to help them quickly learn the correct way to use them.

- The backflow incense cone machine can be customized with molds such as pagodas, gourds, cones, lettering, patterns, and logos. The diameters and lengths of the finished products can also be customized to suit the customer’s needs.