Features at a Glance

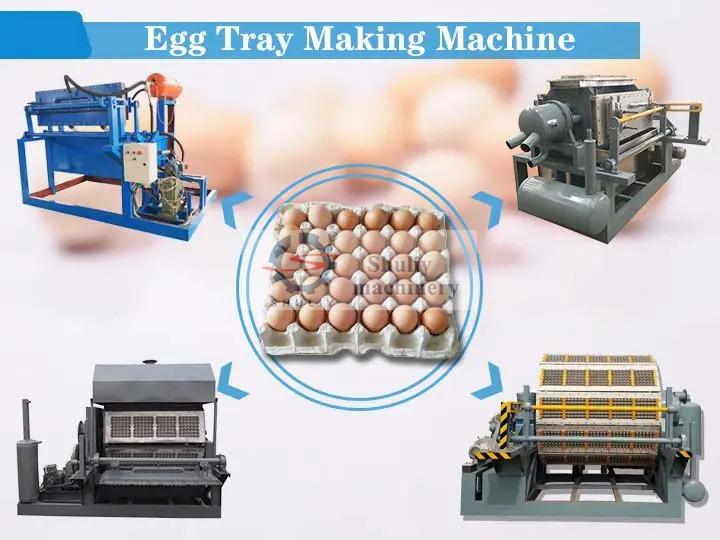

The industrial egg tray machine is a pulp forming equipment that can recycle various types of waste paper and process it into pulp trays of various specifications.

This egg tray making machine is mainly used to process egg trays of different sizes. Egg tray processing includes waste paper crushing, pulping, pulp molding, egg tray drying, etc. Among them, pulp forming equipment is the key equipment in the egg tray production process.

In order to meet the needs of different customers, shuliy factory has designed a variety of different models of egg tray machines, with outputs ranging from 1,000pcs/h to 7,000pcs/h.

Different models of egg tray machines have different production capabilities, processing efficiency, water and electricity consumption, configuration, etc. Our factory can recommend suitable egg tray machine models and accessories for customers based on their basic needs.

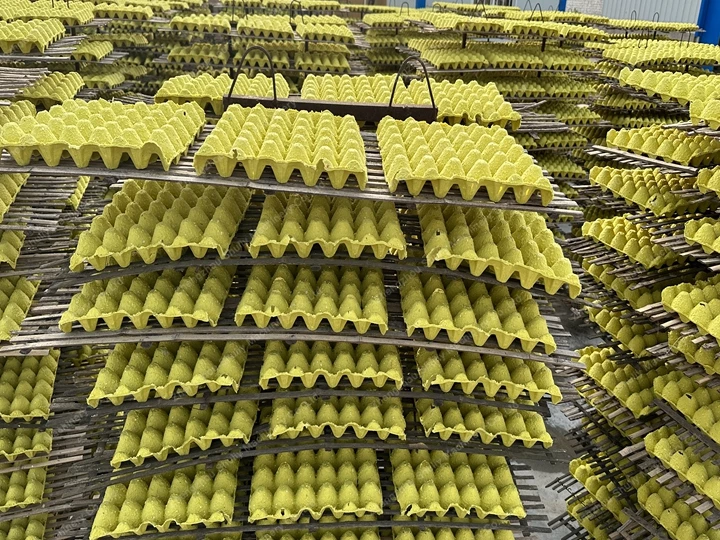

Final products of egg tray machine

As a multifunctional pulp molding machine, the egg tray machine can be used to process all kinds of pulp trays, such as fruit trays, coffee trays, instrument trays, disposable medical trays and so on, by changing different molding dies. No matter which specification of pulp trays you like to process, our factory engineers can customize the right molding die for you.

Egg tray machine features

The egg trays making machine is the most important machine in the egg tray production business. This commercial egg carton machine adopts the principle of hot press forming.

The paper pulp transformed into fiber suspension is evenly coated on the surface of the mold, and then it is pressed to form the egg tray.

Types of egg tray machines

This machine can be divided into the single-sided egg tray machine and the multi-sided egg tray machine. The multi-sided egg carrier can also be divided into the 4-sided egg tray machine, the 8-sided egg tray machine, and the 12-sided egg tray machine.

The final product of the egg tray forming machine is mainly related to the mold, and different products can be produced by replacing different molds.

At present, this machine is mainly used in the production of egg trays, wine trays, apple trays, toy mold holders, electronic component packaging, and so on. It has good shock-proof and buffer functions and can avoid collision during transportation.

Parameters of Shuliy’s egg tray machine

| Model | Capacity | Power | Voltage | Weight | Paper consumption | Water consumption | Size(molding machine) | Drying method |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900mm | Dry naturally or use a dryer |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900mm | Dry naturally or use a dryer |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800mm | Brick kiln drying or multi-layer dryer |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800mm | Brick kiln drying or multi-layer dryer |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500mm | Brick kiln drying or multi-layer dryer |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500mm | Brick kiln drying or multi-layer dryer |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500mm | Brick kiln drying or multi-layer dryer |