废旧纺织品/棉花回收生产线包括纺织纤维切割机、纤维开松机、清弹簧机、立式液压打包机。每台机器都有其独立的功能,是纤维回收不可或缺的一部分。

纺织纤维切割机

光纤切割机是此过程的第一步。操作人员只需将需要切割的材料放在送料传送带上,机器就会按照指定的尺寸进行切割。省时省力,是废旧布料回收处理的最佳选择。

纤维开松机

材料经过纤维切割机加工后,下一步就是松开。将压实和缠结的纤维原料解开并除去杂质的过程。

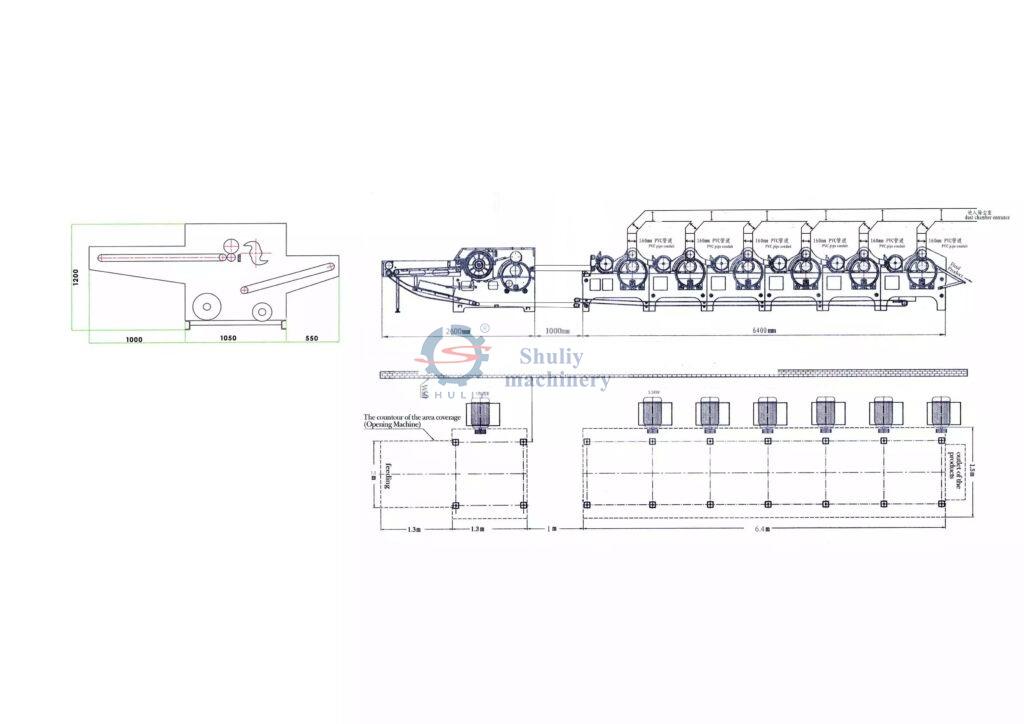

清弹簧机

一般来说,开清机通常采用组合形式。当然,清纱机广泛应用于各种化纤、麻纺、棉纺、毛纺、纺织废纱、废旧衣物、纺织边角料、无纺布等原料的开松。

立式液压打包机

经过一系列的流程之后,就到了最后一步:包装。立式液压打包机可有效减少废物储存空间,最多可节省80%堆放空间,降低运输成本,同时有利于环境保护,有利于废物回收利用。