EPS聚苯乙烯泡沫造粒线

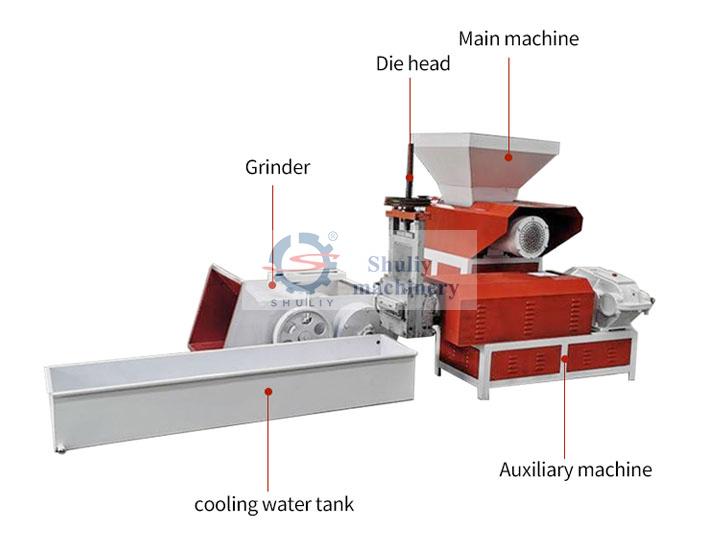

EPS聚苯乙烯泡沫造粒线可以将聚苯乙烯废旧泡沫加工成颗粒。该生产线包括制粒机、水箱、颗粒切割机、控制柜。主机为EPS泡沫造粒机,包括两台机器,集破碎和熔融功能于一体。

EPS泡沫造粒机

- 型号: 220+150

- 功率:15kw+5.5kw

- 产能:150-200kg/h

- 双减速机

- 电动模具如图(不停机换网)

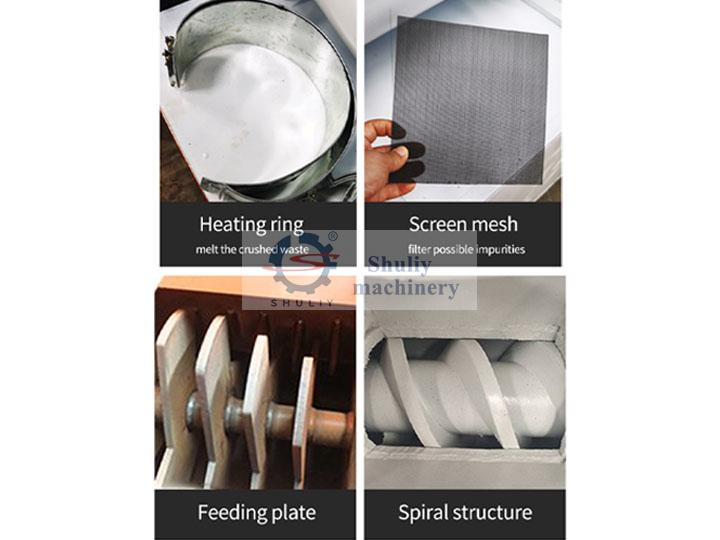

该泡沫造粒机包括破碎机和造粒机。 EPS泡沫造粒机由辅机、主机、模头、粉碎机组成。根据输出的不同,它有不同的类型。由于EPS泡沫在加工过程中容易产生碎片,客户可以用布盖住进料口。

水箱

该冷却机用于冷却塑料颗粒并将颗粒送到下一步——塑料切割机。客户也可以根据自己的需求定制罐体,但最常见的长度是3米。

颗粒切割机

本机用于将塑料条切成小块,颗粒的尺寸可根据您的要求进行调整。

控制柜

温控柜控制塑料颗粒机的温度,也方便人们操作机器。

什么是EPS聚苯乙烯泡沫和EPE保丽龙?

EPS(发泡聚苯乙烯)是一种轻质聚合物。它采用聚苯乙烯树脂添加发泡剂,同时加热使其软化并产生气体,形成硬质闭孔结构泡沫塑料。

这种均匀封闭的空腔结构使EPS具有吸水率低、保温性好、重量轻、机械强度高等特点。 EPS可以模压成型,即可以预先发泡成颗粒,然后在模具中成型为各种形状。韧性较差,易断裂,缓冲性能一般。

EPE(可发性聚乙烯)俗称珍珠棉。密度小、柔韧性好、回收率高。防震性能优良,独立气泡结构,表面吸水率低。抗渗性好。耐酸、碱、盐、油及其他有机溶剂,具有优良的耐老化性能。高温下不流动,低温下不龟裂。

EPE可以挤出或发泡,制成板材、片材或管材,然后冲切、粘合成型。韧性好,不易断裂,具有良好的缓冲性能。